Refining

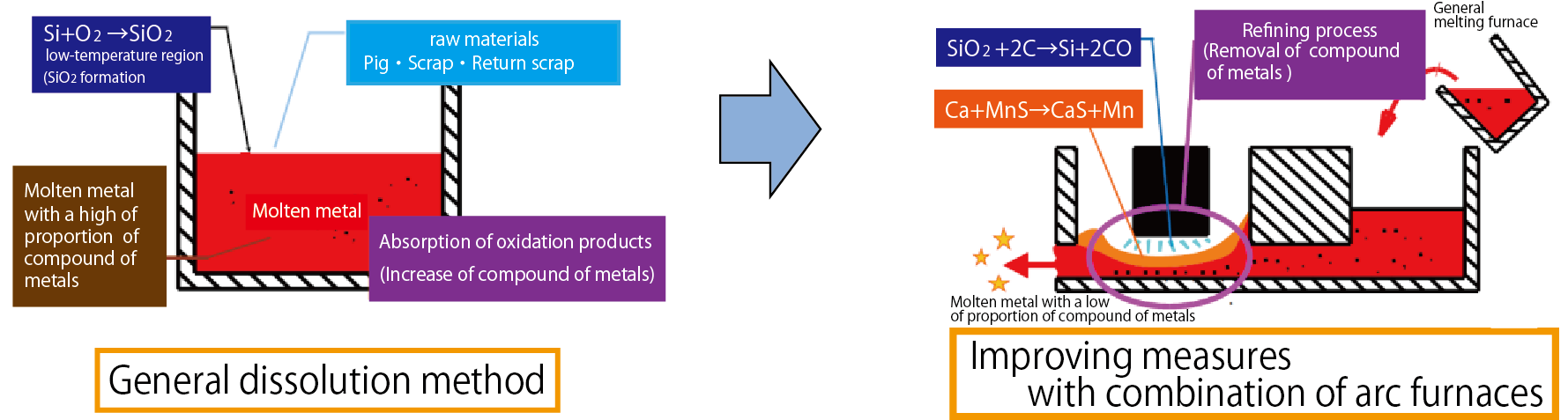

Defect generation in cast iron has much to do with compound of metals in molten metal, and the key for improved quality is affected by how much compound of metals is reduced.

KS furnace refines compound of metals using resected off-scourings as crude material. While the refining furnace re-refines the molten metal by the disposal with arc slag and removes the compound of metals after using common high-frequency furnace.

This method overcames the constraint of raw materials because we can use regular pig, scrapped, and any kinds of iron as the materials.

In addition, the refining furnace makes huge disposal possible since only refining is needed after the fusion. This means can be used in the fields which have a need for bulk production such as the automobile industry.

============================================================================

You will jump to every particular item if you click them.

1.The Method of Improvement

2.The Development Goal and the Past Achievements

3.The Future Development

============================================================================

↑An enlarged image will be displayed if you click the above image.

Developing Equipments and the Establishment of Operation

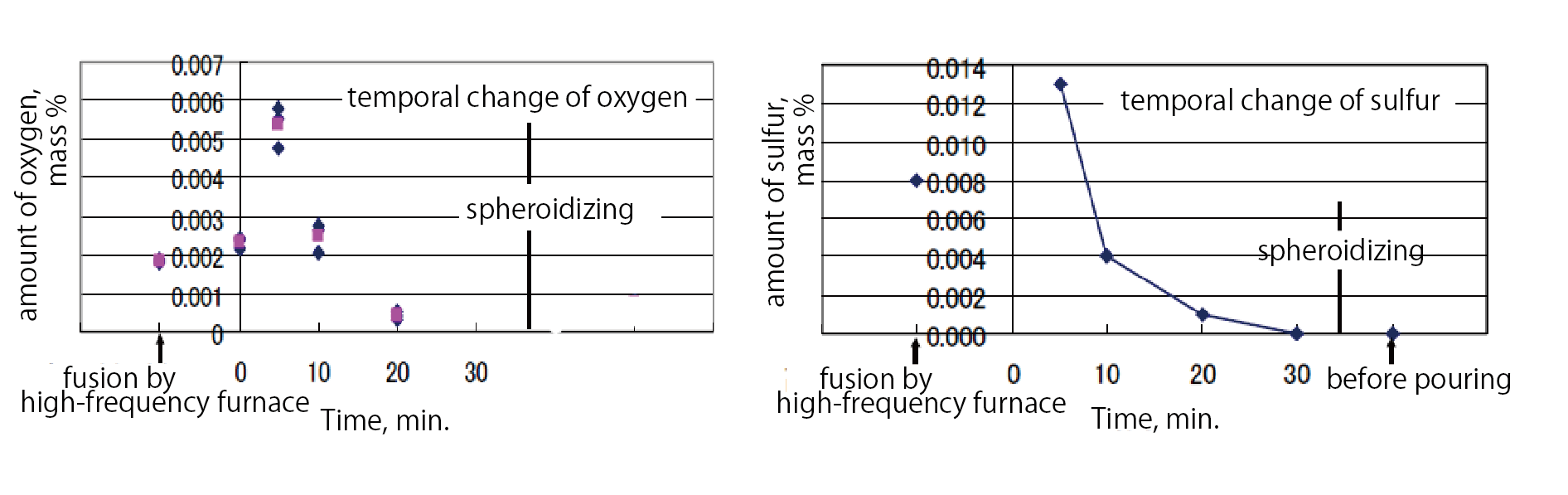

We completed the validation of specification of actual equipment and operationg condition with combination of arc furnaces and ensured that our goal “O<20ppm S<0.008%” could be accomplished.

↑An enlarged image will be displayed if you click the above image.

Fluidity was dramatically improved by lowering of compound of metals. The consequence is shown below.

↑An enlarged image will be displayed if you click the above image.

Development of Simplified on-site Test for Quality Identification

As presented above, temporal behaviors in sulfur content and amount of oxygen are abundantly fitted, and we can keep up consistent production by monitoring sulfur’s quantity as the control index of molten metal quality in operating.

The method makes good fluidity, and it hardly generates clump; therefore, we have aimed for applying the method to complex and valuable products. Coinstantaneously, we have also forwarded the search and development for applicable product.

Also we can offer high grade products no matter how low-gluten and high Mn scrap is used as noted in another page, so we continuously provide combined system as a device to you.